0 Piece,Product Price: US $ 0

Product Description

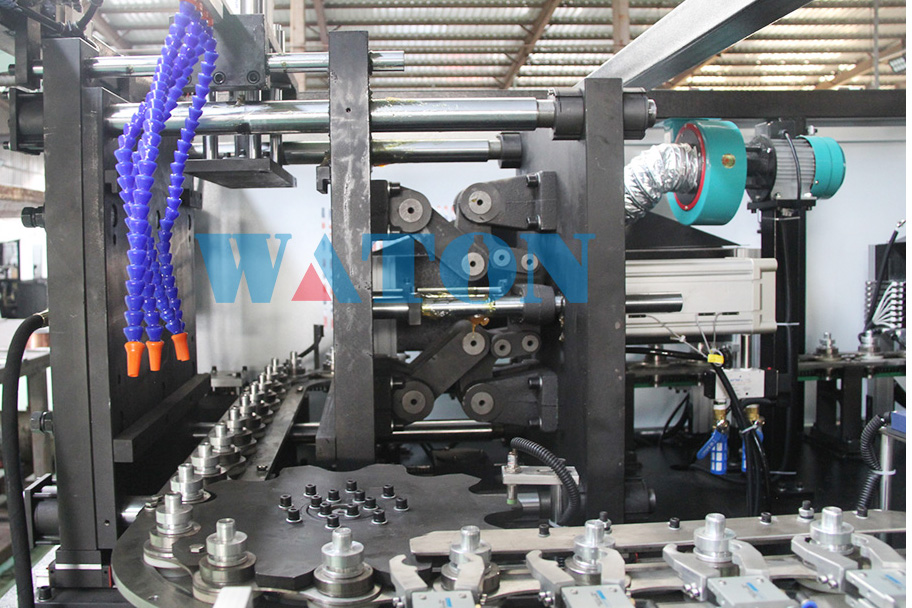

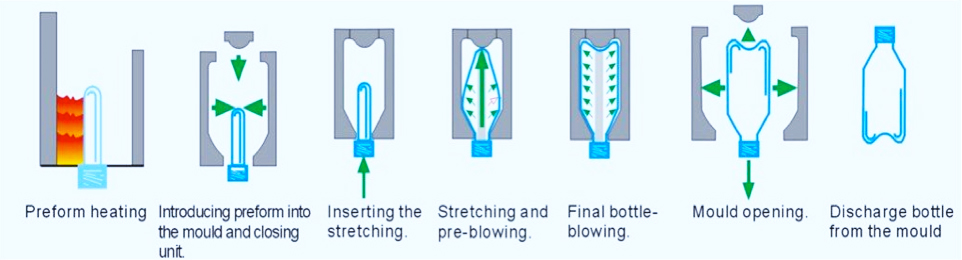

ECO-4L 4-cavities ECO Series Auto Blow Molding Machine linear full-auto stretch blow molding machine, is an economical full-automatic PET bottle blowing machine independently developed by WATON Machinery. It is economical, fast and convenient. It can produce all kinds of bottles below 2000ml, including food packaging bottles, edible oil bottles, soda and mineral water bottles, fruit juice bottles, wine bottles, cosmetics bottles and so on.

1. Upgrade to Servo Motor Drive:

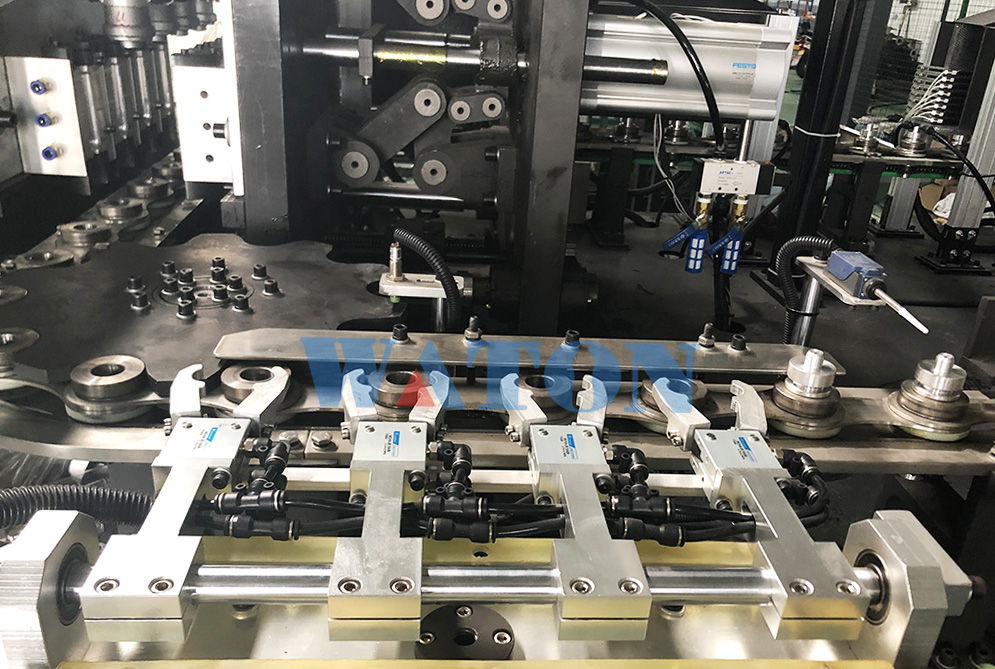

a. Preform Feeding System: Servo Motor controls, high speed and precisely positioning.

Preform Feeding Chain adopts composite Nylon polymer, light, wear resistant, no deformation. Dimension on Nylon chain is made according to Preform Neck size. Perfect matching to avoid preform stuck and reduce friction between preforms.

b. Preform Transfer System: preforms horizontal movements are driven by Servo Motor. Make preforms 4pcs/6pcs as one unit, overall simplified stepping motion, achieve high-speed positioning and smooth motion. To complete one step cycle, the Servo Motor drive gear rotate only one-third of a turn. Speed of preform moving is 2 times of Cylinder Driven way.

2. Mold fixing by Drawer Design.

Push the mold, fix the positioning screws. Mold changeover work can be easily done in half hour.

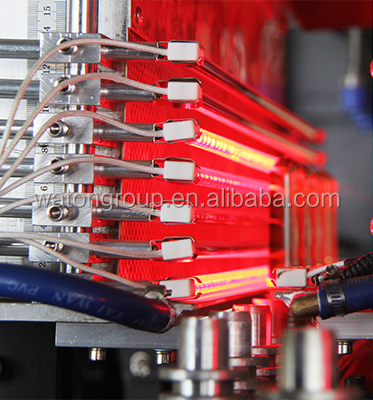

3. Efficiency Constant Temperature Oven:

a. The most advanced high frequency Infrared Lamp, increase heating efficiency 30%-50%.

b. Each layer of lamp are separately controlled, with assistant ruler on machine.

c. Intelligent temperature control system.

Temperature detector feedback to PLC automatically, PLC makes accurate judgment and then control circulation air in oven. It leads to constant temperature in Oven, free from voltage fluctuations and ambient temperature. It works when large ambient temperature difference (-28~45 ℃).

d. Preform self-rotation System, ensure every side of every preforms are heated evenly, which ensure quality of blown bottle.

e. Neck Cooling in Oven.Preform Necks are cooled by recycling water, which avoid neck deformation.

FAQ

Q1: Can I visit your factory and send team for learning and inspect?

A1:Yes,sure.We will do our best to teaching you how to use the machine.welcome to visit our factory!

Q2: What your advantages are?

A2: 1. Stable running machines with newly technology, competitive price;

2. top rank technical support

3. Best and prompt service

Q3: Where is your factory located? How can we visit there?

A3: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q4: What is your terms of packing?

A4: Because of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

Q5: When Can I get my machine after I paid?

A5: The delivery time is about 30-45 working days.