Newest Stainless Barley Malt Mill Grain Grinder Crusher Hand Craft Grain Mill Crusher Home Brew Beer Machine Wholesale

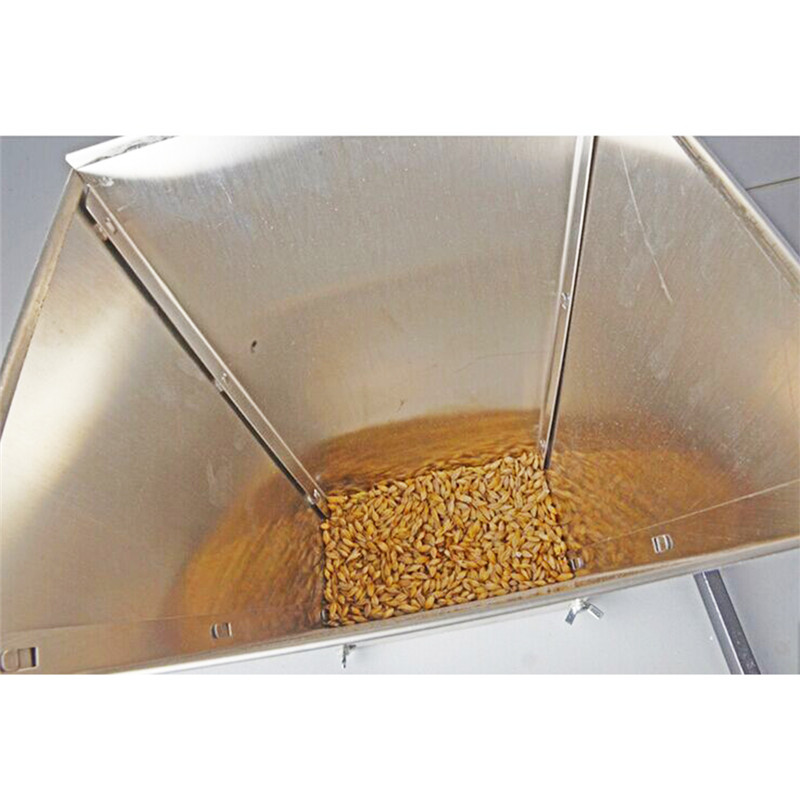

This Grain Mill is constructed using materials that will last a lifetime. Cold rolled steel for the rollers before, but now they are updated,. 6061 Aluminum body and hopper and oil impregnated brass bushings. The grain mill is professional in grinding barley, wheat and other cereals. It is provided with adjustable 3- steel rollers which can be crushed cereal well and peeled shell off perfectly, so as to be good for brewing beer in future.

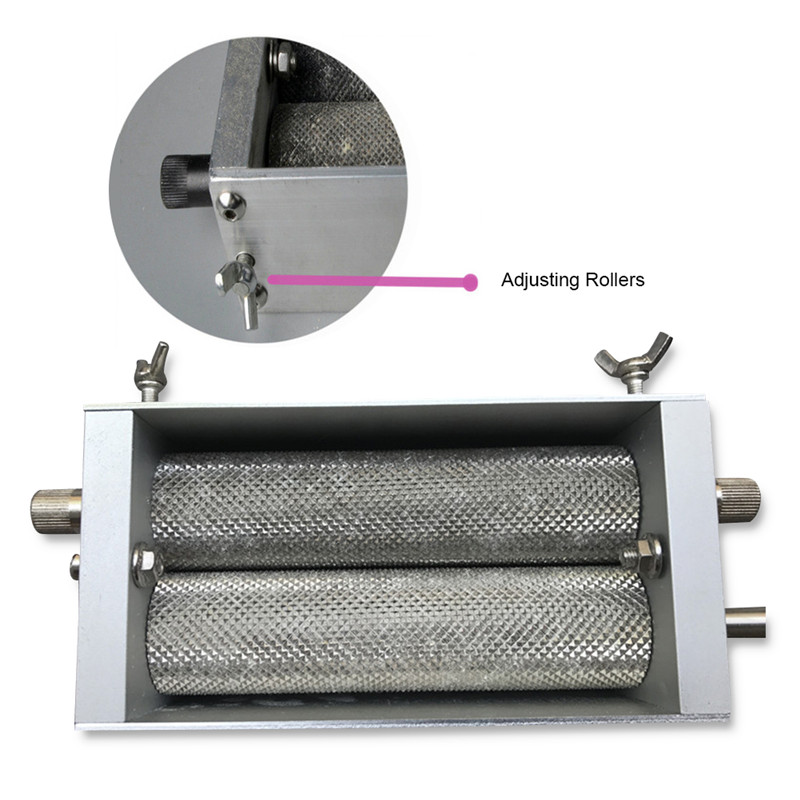

This equipment is perfect for large batches and high efficiency milling. With rollers, all your grain will be crushed twice in one cycle. The initial pass slightly flattens the grain, getting it ready for the next crush that breaks apart the grains and loosens the starch with minimal husk damage.

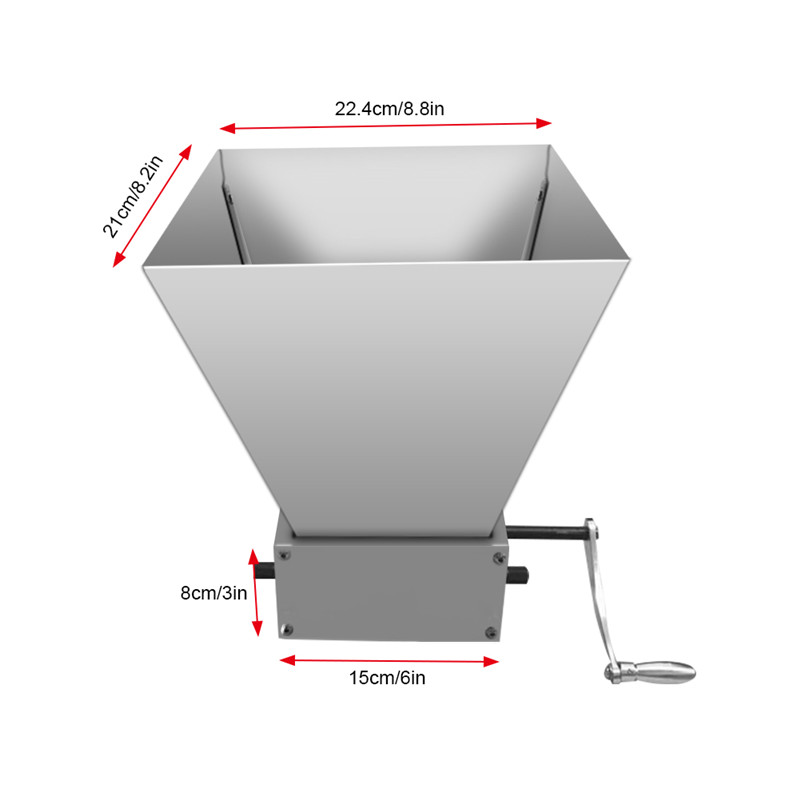

The aluminum hopper can hold up to 11 lbs of grains and the roller body features an alloy block frame that houses two steel rollers on oil-impregnated bronze bushings. The drive shaft and all axles are integral to the roller, which makes clockwise or counter-clockwise drive possible. A hand crank is included, but the mill can be easily motorized with a corded electric drill. You don't need any additional attachments, just stick the drill on and go. Knurled knobs allow a gap spacing adjustment range of .070"". Adjusting is simple - just loosen the adjustment screws, adjust the gap and tighten the adjustment screws. You will need to supply or build a base to set the mill over a grain bin or 5 gallon bucket.

Parameters:

Type: Grain crusher

steel rollers: Carbon steel

Grinder housing: Aluminum 6061

Hoppers: Aluminum 6061

Total height: 263mm

Hopper dimensions at top: 223 x 210mm

Footprint size of grinder: 150 x 75mm

Dimensions: 76 x 150 x 50mm

Steel Rollers: ø 28 x 127mm

Adjustable distance: 0,025 - 0,1 inch (0.635 - 2,54 mm)

Crank handle: 200mm

Package weight: 3350g

Features:

Width and roller diameter is optimized for use with power drill

Adjustable rollers at both ends to give uniform crush

12 TPI knurl to efficiently pull grain through rollers while leaving hull intact to form an excellent filter bed for sparging

6"" long adjustable gap

Fully adjustable mill

0.060 fixed primary gap, 0-0.065 fully-adjustable secondary gap

Dual eccentric adjusters built from stainless steel for no galling

8 lbs / minute is average throughput

6"" x 1.5"" diameter steel rollers

Crankshaft can be turned clockwise or counterclockwise

Durable alloy frame

SAE 841 oil impregnated bronze bushings

Heavy-duty two roller mill with adjustable secondary gap-spacing

Integral drive shaft and axles

Mill can be hand-cranked or motorized with a corded electric drill

You will need to supply or build a base

Package include:

1*MaltMill Included

4*pcs hoppers

1*pcs crank handle

1*bag screws and 2pcs rollers