0 Piece,Product Price: US $ 0

| Quantity(Set/Sets) | 1 | >1 |

| Est. Time(days) | 30 | To be negotiated |

If you finish the payment today, your order will ship out within the delivery date.

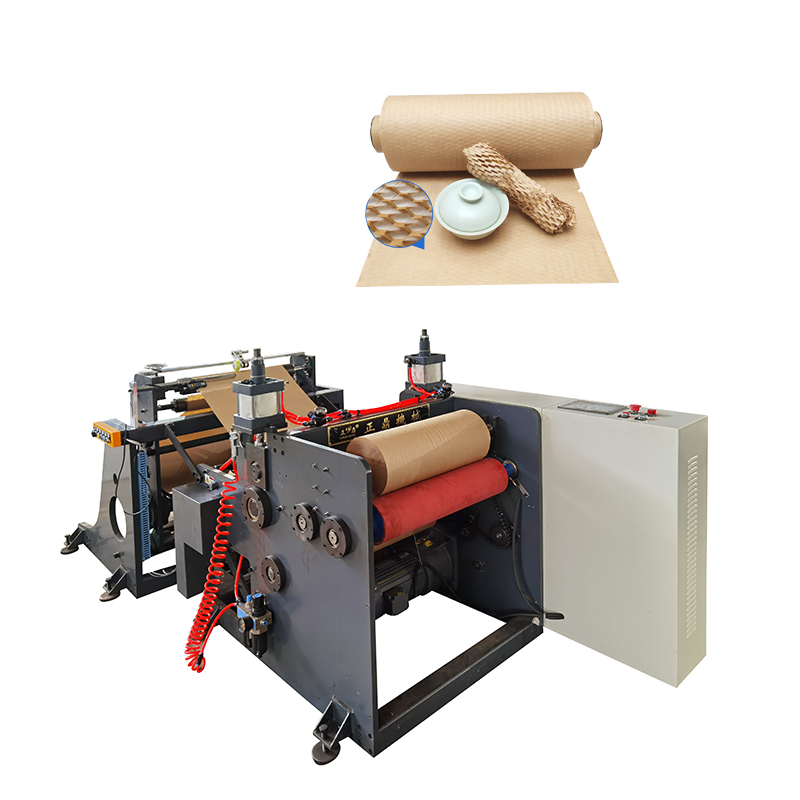

YD-500 Bubble Wrapping Honeycomb Roll Paper Production Line Machine

The end products features as follows:

1. Perfect for start-up or home based web shops

2.Excellent surface protection and presentation

3. A sustainable alternative to bubble wrap

4.Paper is a combination of a patented die cut Kraft paper with a tissue interleaf paper. The Paper converter expands the die cut paper to a 3D honeycomb structure providing a unique packaging product whilst also reducing material handling and taking up less storage space.

Honeycomb Paper Rolling Cutting Machine is a special machine for making honeycomb paper. It can cut kraft paper into horizontal points and break lines by means of rolling cutting, and harvest a roll of material by means of surface rewinding. After rewinding, the roll material can be used for express buffer packaging, and also can be used for the middle buffer layer of express buffer packaging bag. From unwinding to winding completed once.

We also have other paper devices:

1. Honeycomb Paper Envelope Machine: paper bags produced by it can replace bubble film bags and have a good buffering effect.

2. Paper Bubble Envelope Machine: paper bags produced by it can replace bubble film bags and have a good buffering effect.

3. Corrugated Paper Envelope Machine:

4. Bottom Gusset Bag Machine: paper bags produced by it can replace gray and black film express bags, paper-plastic composite bags, and transparent paper can replace POPP clothing bags, hospital pill bags and so on.

There is no plastic in these bags. They are all glued together. They are completely recycled pulp, which is environmentally friendly in the real sense.

Technical parameters

|

Model |

YD—500 |

|

Effective die cutting width |

510mm |

|

Effective width of tool die |

520mm |

|

Machine speed |

0-130m/min |

|

Unwinding diameter |

0-1200mm |

|

Rewinding diameter |

0-300mm |

|

Unwinding load-bearing(hydraulic hoist) |

1.5T |

|

Unwinding axis |

3” |

|

Rewinding axis |

1.5 "/2" optical axis (one standard size, 1.5 inches standard ) |

|

Machine dimensions (l x W x H) |

2600x1200x1200(mm) |

|

Machine weight |

1700KG |

|

Voltage |

380V 3 Phase 5 wires |

|

Air pressure |

6-8kg/c square meter |